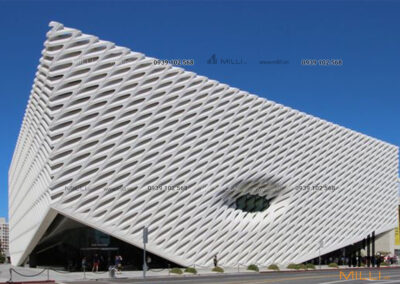

GFRC stand for Glass Fiber Reinforced Concrete. This is a type of fiber-reinforced concrete. The product is also known as glass-fibre reinforced concrete or GRC in British English. Glass fiber concretes are mainly used in exterior building façade panels and as architectural precast concrete.

GRC panel are materials most trusted by architects and investors for architectural today

GRC panel is a new building material that well meets the freedom of design and creativity of architects around the world. GRC materials come in a variety of creative and design styles that can be designed to look exactly like wood or natural stone with a beautifully polished surface finish.

The material composition in the GRC panel is the reason for the versatility of this material. With high strength, good compressive strength, it is easy to create products of various shapes and sizes.

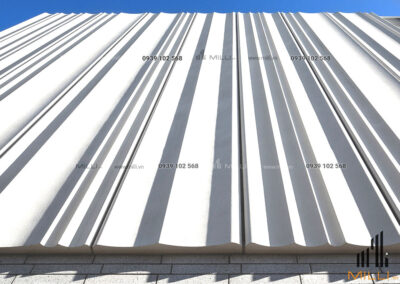

GFRC panel – A material that enhances the aesthetic value and protect of the building

GFRC panel also known as Glass fiber reinforced panel concrete is fast becoming one of the most commonly used construction materials and the material of choice for architects who are looking to add high quality, durable architectural features to buildings and structures. This is because GFRC is known to be tough, strong, lightweight and versatile for hundreds of uses. Even better is the fact that GFRC does not need further reinforcement.

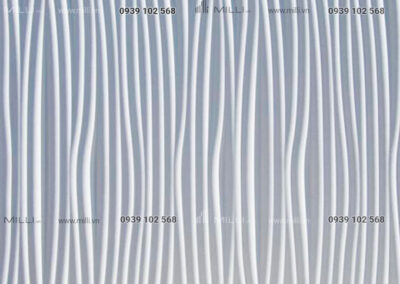

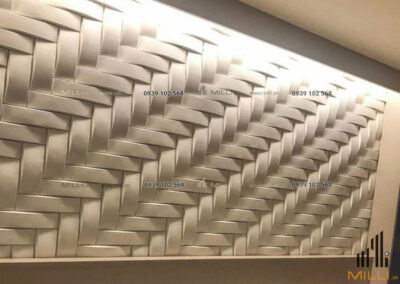

3D cement tile – New trend of interior and exterior decoration 2023

3D cement tile is a new material that is shaped and shaped with many modern 3D textures and patterns. They are finished with textured surfaces for the purpose of the designer, but they are used to decorate the facade wall, living room, bedroom, stair wall…

Today, with the improvement of materials, 3D bricks not only have cement colors but also have many different sizes. Materials and colors, helping to optimize construction time and better finish the decorative array.

Concept of GRC material

GRC is a new building material in Vietnam today. GRC is also known as glass fiber concrete – a type of coarse fiber reinforced concrete mixed in a mixture of fine aggregates: cement, clean water, clean sand, polymer, colorants and plasticizers. So what is GRC fiber glass concrete?

GRC fiberglass concrete is made by molding and injection method, which ensures to maintain the physical and chemical uniformity of the fiberglass and mortar content. GRC fiberglass concrete has a wide range of products for the modern construction industry.

Fiberglass concrete (FRC) easily creates large facade GRC panels, giving unique architectural features to building facades and it is lighter than reinforced concrete. In addition, GRC panel is also applied in decorating architectural details such as moldings, column tops, interior decoration, garden landscaping and shaping in fine art decoration.

Why use GRC panel?

GRC panels are lightweight, accounting for only 20% of the total weight of conventional concrete, helping to reduce the load on buildings.

Especially, GRC material is thinner than concrete, which helps to save maximum materials for product composition.

In addition, GRC panel contains glass fiber content and plasticizers to help the product have better tensile and flexural strength than pre-cast concrete.

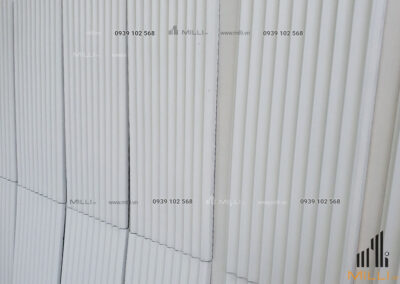

GRC panels come in a variety of vibrant colors and surface finishes, shaping products in a variety of designs, allowing for creative designs, yet remaining true to the traditional character.

GRC material is a finished molded product, which has been treated for waterproofing and acid-fixing during production. When installed at the construction site, it will ensure absolute waterproofing, not affected by the effects of weather, so there is almost no need for too much maintenance. Finished products also help speed up the construction progress and ensure the progress of the work. The constructions using GRC materials are not affected by extreme weather such as too cold, fog or heavy rain.

It is fireproof and environmentally friendly, ensuring green standards for projects.

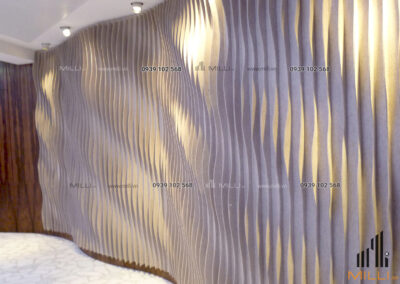

GRC panel has a variety of design styles and creativity

GRC panels can be floor-to-ceiling lengths, accompanied by intricate decorative lines without disrupting or reducing structural integrity. Besides, GRC also has a standard surface finish such as wooden or stone panel, concrete.

In addition, GRC panel is a good substitute for natural stone, helping to reduce transportation costs and easy installation at the site. Because GRC material is very light, manufactured exactly like natural stone, it is often used in stone cladding works, stone waterfalls or as landscape stone for garden decoration.

GRC is a multi-colored material with a beautiful delicate surface finish to any color. Decorative colored stone or glass can be added to the mix to create a granite-like surface.

This aesthetic flexibility is further enhanced by adding color effects directly to GRC panels, including adding a variety of aggregates, pigments and sands to the GRC mix. Production of this material also undergoes a sand blasting treatment, providing new look and design possibilities. In addition, visual effects can be created by mounting or casting bricks.

Does glass fiber reinforced concrete have any disadvantages?

The mechanical properties of GRC panel make it ideal for various requirements. However, one potential disadvantage for some users is the cost of GRC panel.

It can be expensive to use when compared to ordinary concrete. Of course, the added cost comes with additional strength and several other benefits, already mentioned in previous sections.

Contact us! Whatsapp: +84 939 102 568

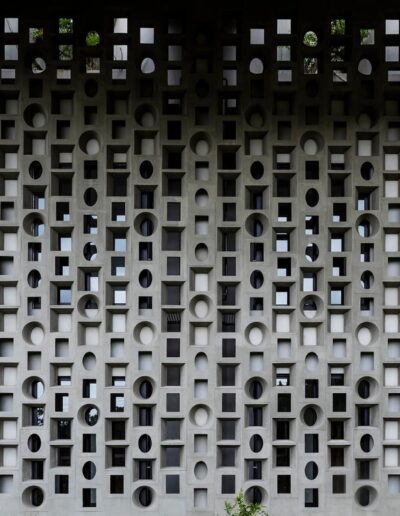

A breeze block is a typical building block made of concrete and ash. These concrete blocks are usually known as breeze blocks or cinder blocks even if ash is not present in them. In some parts of the world, these concrete blocks can also be manufactured along with gravel, clinker, and sand, used as fillers.

Breeze block is a material that many people trust and choose for classic and modern architecture. This product not only helps to keep the house airy. Get natural sunlight and wind. It also creates an attractive and impressive beauty for the front of the house. For more useful information about this line of tiles, please join Milli Tiles to learn the article below!

3D cement tile is a new material that is shaped and shaped with many modern 3D textures and patterns. They are finished with textured surfaces for the purpose of the designer, but they are used to decorate the facade wall, living room, bedroom, stair wall…

Today, with the improvement of materials, 3D bricks not only have cement colors but also have many different sizes. Materials and colors, helping to optimize construction time and better finish the decorative array.