GFRC panel also known as Glass fiber reinforced panel concrete is fast becoming one of the most commonly used construction materials and the material of choice for architects who are looking to add high quality, durable architectural features to buildings and structures. This is because GFRC is known to be tough, strong, lightweight and versatile for hundreds of uses. Even better is the fact that GFRC does not need further reinforcement.

Products can be used in the design and implementation of building elements not only in the exterior but also in the interior design. Thanks to the wide use of imprinted matrices, it is easy to achieve the full spectrum of different surface areas not only for cladding plates and GFRC panel. But also for more complex architectural elements, shaped and space elements and design solitaires.

What is GFRC panel?

GFRC (Glass Fiber Reinforced Concrete) is a new construction material in Vietnam today. GFRC is also known as glass fiber concrete – a type of coarse fiber reinforced concrete mixed in a mixture of fine aggregates: cement, clean water, clean sand, polymer, colorants and plasticizers.

Product is made by molding and injection method, which ensures to maintain the physical and chemical uniformity of the fiberglass and mortar content. GFRC fiberglass concrete has a wide range of products for the modern construction industry.

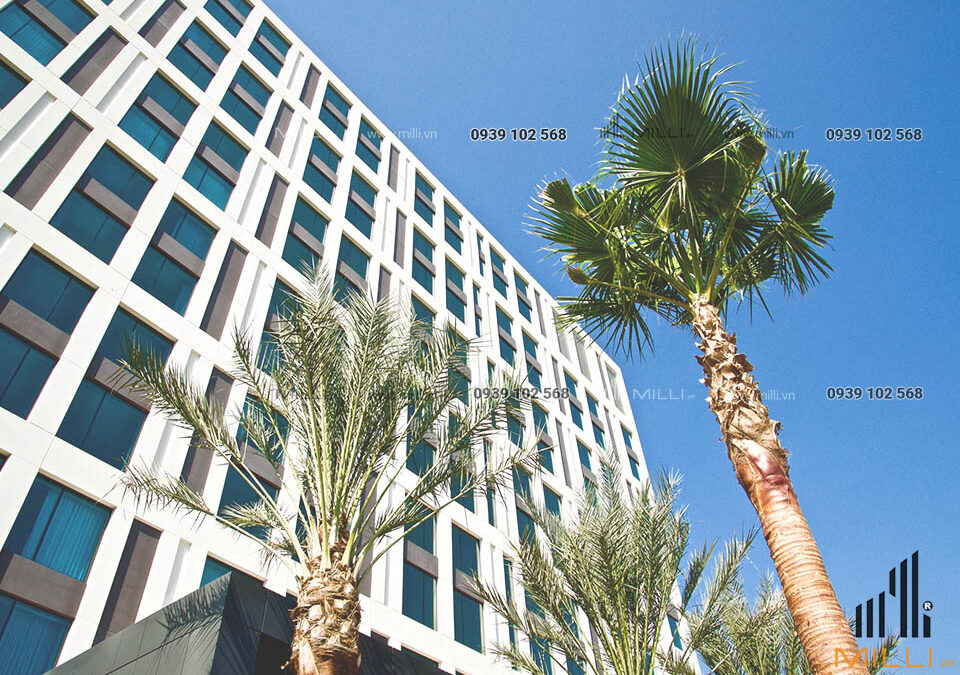

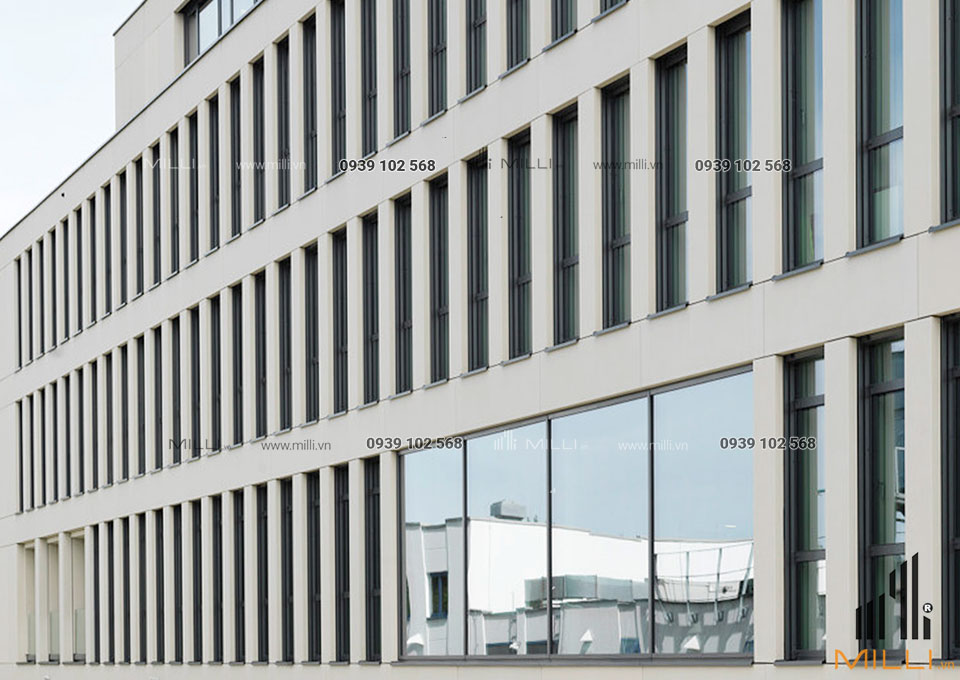

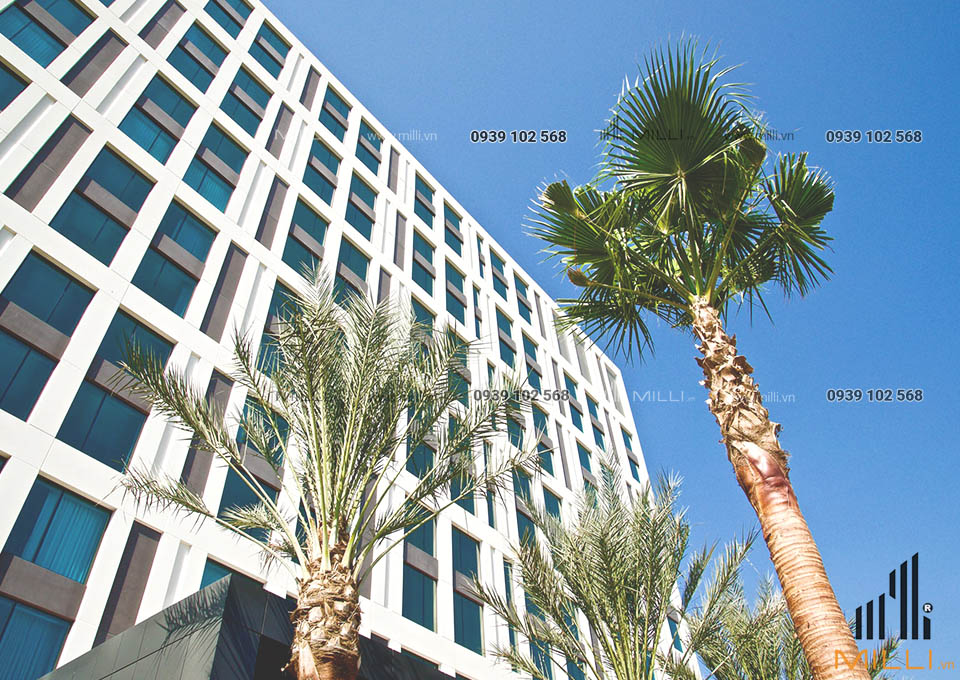

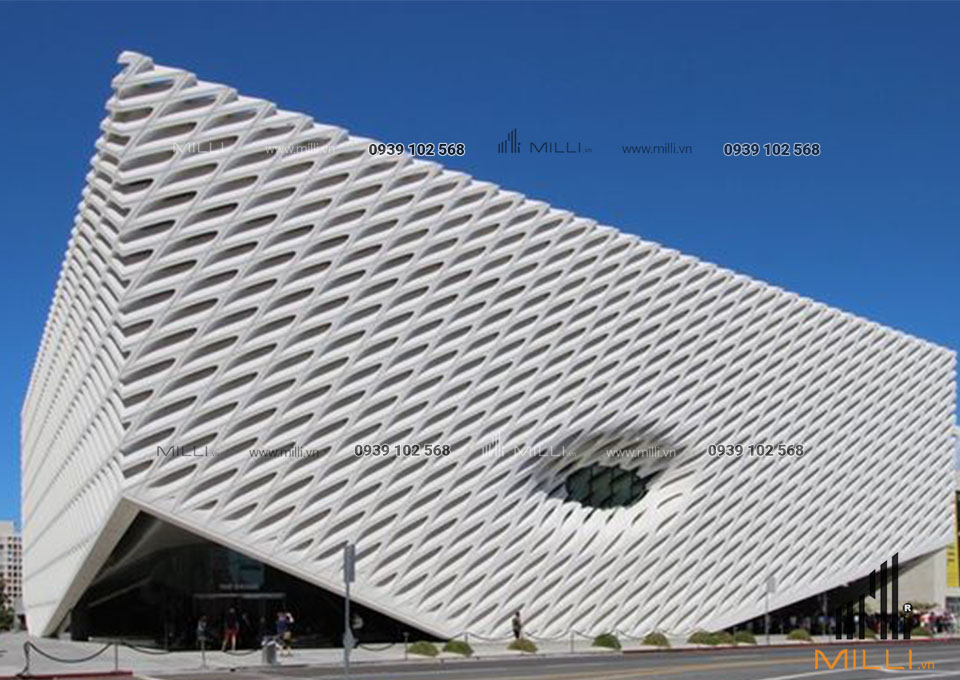

GFRC easily creates large facade panels, giving unique architectural features to building facades. And it is lighter than reinforced concrete. In addition, GFRC panel is also applied in decorating architectural details such as moldings. Column tops, interior decoration, garden landscaping and shaping in fine art decoration. So what is GFRC panel?

GFRC panels are elements of GFRC in a designed shape that can be fix onto the substructure. For example these can be square, rectangular, trapezoidal or round. The size and shape is defined by the design of each particular project. GFRC panels can create standalone cladding or can be a part of united facade or a combined system.

Why use GFRC panel for projects?

So many of the benefits of using GFRC panel in place of traditional concrete add up to one very big advantage – cost effectiveness. Here is a rundown on what makes this building material cost effective.

What Does Cost Effective Mean?

Cost effective does not mean cheap or low cost. What it does mean is that the product or service does offer value in terms of the money spent and the return it will offer. Usually this relates to the return that the person receives after spending the money and how that return will either save money or create an intangible benefit.

While there may be cheaper building materials out there, these may not be cost effective like GFRC panel. Which offers significant benefits that the other materials cannot deliver.

Any product that is produced and used on the market, in addition to the advantages it brings to the user, still has certain disadvantages and limitations. The same goes for GFRC panel. It has the advantage of being thin and light, diverse in design, giving constructions a modern and luxurious beauty, but it still has some disadvantages of its own. So what are the advantages and disadvantages of product ? We also learn about the advantages and disadvantages of GFRC panel, so that we can make the best choice when building buildings.

Advantages and disadvantages of GFRC panel

There are a number of ways that value is created with GFRC as compared to other building materials commonly used:

Advantages

Product has high aesthetic value

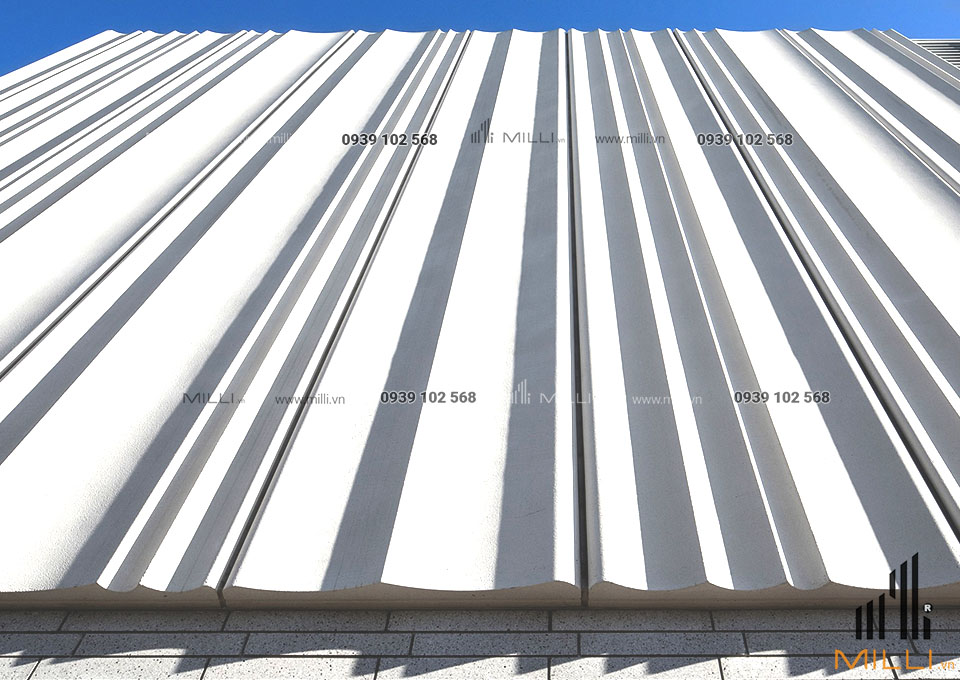

GFRC panel are formed by injection molding or by machine injection from a pre-mixed mortar mixture. So it is easy to create products with diverse designs. Depending on the architecture of each building, it will create different types of facades with different beautiful designs, diverse natural colors, and can create complex shapes such as: curved, folded, wavy… The products be application brings unique and impressive features to the facade of each building.

Easy to compress, shape

As an innovative product, GFRC panel can also be shaped into virtually anything as well as made to look like any other type of building material and in any color. This means it can be formed into a wide range of architectural products that other materials simply cannot.

GFRC panel is durable

With a lower weight and significant higher strength, its performance is second to none. Which means it is made to last through all types of contact, including water, fire, seismic activity, wind and extreme temperature changes. Lab tests have confirmed its high resistance and durability over time as well as its ability to perform better than other materials like concrete. Although it is lightweight, one of its biggest benefits is its incredible strength and durability, offering more than traditional concrete. Here’s why and how.

Low Maintenance

Not only is GFRC panel made to last, it also requires very little maintenance. This saves on other types of costs that are often part of the equation if other building materials were uses.

GFRC panel is easy to install

Because of the lighter weight, GFRC is easier to transport, handle, and install. This can cut project time and labor costs, making it very cost effective over other materials that are heavy, cumbersome. And require larger equipment to install. Because of this lightweight feature and strength combined. GFRC can often be uses in new ways for construction projects, including pre-cast concrete panels for a building.

Environmentally Friendly

There are a number of reasons to use GFRC as an environmentally friendly building material:

- It is made up of stable and inert natural minerals that are not considered pollutants or toxic in nature, which means that it is not polluting the air or water.

- GFRC often uses recycled aggregates, glass fiber, sand and cement in its production.

- Its durability means that there are fewer building projects to restore a structure, which reduces emissions, saves fuel and energy, and minimizes waste.

- Since it can be finish and painted prior to installation, this further reduces air pollution.

- Its lightweight design means easier to transport and fewer trips to the construction site are require.

- Overall, less material by volume is require for construction projects. Which means that this is more efficient and not wasteful like traditional building projects.

In the construction industry, the regulatory environment is changing and requiring more ‘green’ materials. Switching now to an environmentally friendly building material like GFRC can create a competitive advantage. And remove any future costs or potential penalties for emissions or pollution.

Additionally, the GFRC panel helps the inside of the building in many ways as well to also use less energy over time and provide a comfortable environment for its inhabitants. The material is good for insulation purposes, keeping the temperature of the structure regulated so that it is cool in summer and holds the heat in winter. This means less use of artificial heating and cooling. This is also an important aspect of creating a green building.

Disadvantages

The mechanical properties of GFRC make it ideal for various requirements. However, one potential disadvantage for some users is the cost of GFRC panel.

GFRC panels can be expensive to use when compared to ordinary concrete. Of course, the added cost comes with additional strength and several other benefit.

Depending on the structure and architectural design of each specific project to manufacture and install appropriate GFRC panels.

The implementation of GFRC panel construction is done mostly from the outside of the building. Therefore, it is necessary to prepare lifting equipment, vertical transportation system for employees to work.

Application of GFRC panel in modern building architecture

After learning the introductory information about decorative GFRC panel and the outstanding advantages of this material. We see that this is a material that is well applies to the construction industry today. So how is GFRC material applies in the construction industry in the world and in Vietnam?

In today’s countries, this material plays an important role in decoration and interior materials. Especially in areas with harsh climates. The weather often changes. Decorative GFRC cladding can survive and avoid any external influences. Materials always maintain sustainable aesthetics and features. The following are design ideas that have been create by construction units and architects from GFRC:

Works with high decorative application of GFRC panel:

- Concrete countertops, white fiber-reinforced kitchen island: Investors and customers always prefer pure white on the countertop. After using GFRC sheet, it helps to reduce the weight of the tabletop, while creating durability. Especially the pure white color that the aesthetic requirements put forth.

- Garden interior and exterior decoration: Because it can be molde into any shape. So GFRC panels are suitable for decorating every corner of the garden, aquarium, house wall, … anywhere there is light. Especially it can with stand harsh weather and is a material with high fire resistance.

- GFRC is applies at construction sites in details such as: GFRC facades, GFRC moldings. GFRC column head and garden decoration products, fine art.

Decorative GFRC panel offer freedom. Creativity and natural harmony for architecture. The diversity of this material creates space for personal realization. And unique of each project without any boundaries and limitations. GFRC facade panels can be in flat panel form. Or shaped details – linings, shutters, squares, corners, shutters, etc. The fiberglass reinforced concrete details are manufacture according to the customer’s size requirements.

Is the price of GFRC panel expensive?

GFRC panel provide solutions for flexibility and high durability, replacing natural stone products with large facade panels. The price of GRC panel depends on the design, production and finishing construction and erection at the site. High-quality GFRC manufacturers face few risks, as they consistently provide truly innovative construction solutions for large-scale projects. Depending on the area, there will be different prices, although it is slightly more expensive than regular concrete, but ensures durability and quality for your projects later.

MILLI TILES – SPECIALIZED IN CONSTRUCTION OF GFRC PANEL FOR PROJECTS

MILLI TILES is a leading unit in the field of new construction materials – GFRC fiberglass concrete. We, with the motto of creative, dynamic and effective work of a team of professional, experienced staff, will bring customers and partners satisfaction and trust through each service and product. After referring to the information about GFRC panel with common types of concrete used in construction, we see that: This product has more advantages and in terms of overall cost, using GFRC panel for construction projects. program is very suitable. Contact us today for more information about these durable fiberglass reinforced concrete products!

MILLI CONSTRUCTION MATERIAL COMPANY LIMITED

📱 Hotline: 0939 102 568 📞

We will quote a specific % discount for you depending on the quantity or total value of the order

Contact us to order today, to get the best price support.

Instructions for construction of wind cement bricks, you can read and download below:

FILE INSTRUCTIONS FOR Brick Construction, DOWNLOAD HERE

Contact: Zalo: 0939 102 568

Fanpage: https://www.facebook.com/gachbonggio.hcm/

Youtube: https://www.youtube.com/channel/UC-ePtN2lIBwSp13ADgW7LSA