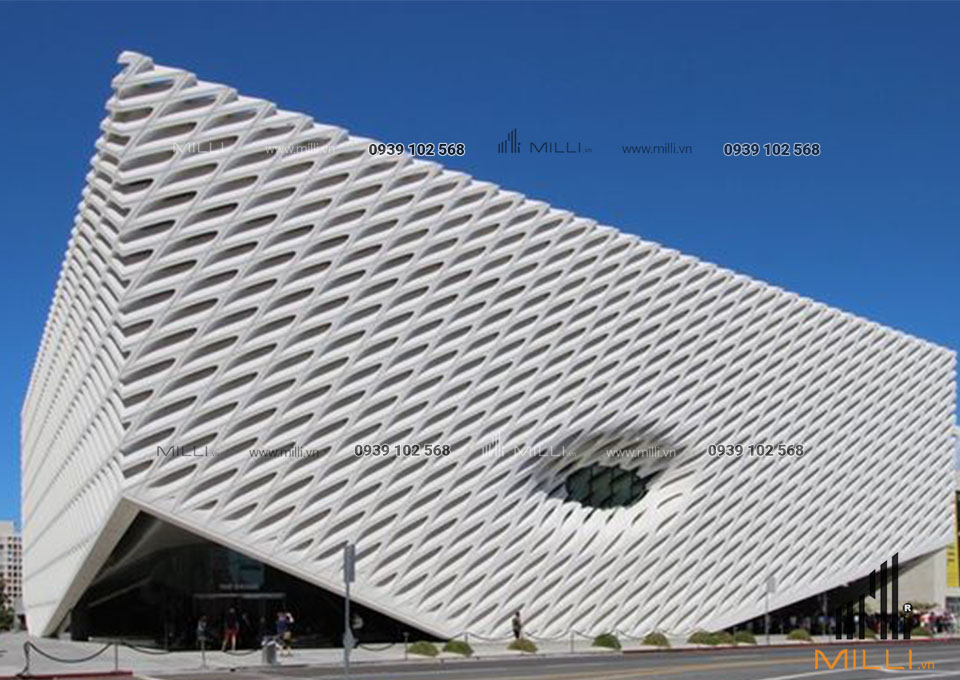

GRC panel are materials most trusted by architects and investors for architectural today

GRC panel is a new building material that well meets the freedom of design and creativity of architects around the world. GRC materials come in a variety of creative and design styles that can be designed to look exactly like wood or natural stone with a beautifully polished surface finish.

The material composition in the GRC panel is the reason for the versatility of this material. With high strength, good compressive strength, it is easy to create products of various shapes and sizes.

Concept of GRC material

GRC is a new building material in Vietnam today. GRC is also known as glass fiber concrete – a type of coarse fiber reinforced concrete mixed in a mixture of fine aggregates: cement, clean water, clean sand, polymer, colorants and plasticizers. So what is GRC fiber glass concrete?

GRC fiberglass concrete is made by molding and injection method, which ensures to maintain the physical and chemical uniformity of the fiberglass and mortar content. GRC fiberglass concrete has a wide range of products for the modern construction industry.

Fiberglass concrete (FRC) easily creates large facade GRC panels, giving unique architectural features to building facades and it is lighter than reinforced concrete. In addition, GRC panel is also applied in decorating architectural details such as moldings, column tops, interior decoration, garden landscaping and shaping in fine art decoration.

Why use GRC panel?

GRC panels are lightweight, accounting for only 20% of the total weight of conventional concrete, helping to reduce the load on buildings.

Especially, GRC material is thinner than concrete, which helps to save maximum materials for product composition.

In addition, GRC panel contains glass fiber content and plasticizers to help the product have better tensile and flexural strength than pre-cast concrete.

GRC panels come in a variety of vibrant colors and surface finishes, shaping products in a variety of designs, allowing for creative designs, yet remaining true to the traditional character.

GRC material is a finished molded product, which has been treated for waterproofing and acid-fixing during production. When installed at the construction site, it will ensure absolute waterproofing, not affected by the effects of weather, so there is almost no need for too much maintenance. Finished products also help speed up the construction progress and ensure the progress of the work. The constructions using GRC materials are not affected by extreme weather such as too cold, fog or heavy rain.

It is fireproof and environmentally friendly, ensuring green standards for projects.

GRC panel has a variety of design styles and creativity

GRC panels can be floor-to-ceiling lengths, accompanied by intricate decorative lines without disrupting or reducing structural integrity. Besides, GRC also has a standard surface finish such as wooden or stone panel, concrete.

In addition, GRC panel is a good substitute for natural stone, helping to reduce transportation costs and easy installation at the site. Because GRC material is very light, manufactured exactly like natural stone, it is often used in stone cladding works, stone waterfalls or as landscape stone for garden decoration.

GRC is a multi-colored material with a beautiful delicate surface finish to any color. Decorative colored stone or glass can be added to the mix to create a granite-like surface.

This aesthetic flexibility is further enhanced by adding color effects directly to GRC panels, including adding a variety of aggregates, pigments and sands to the GRC mix. Production of this material also undergoes a sand blasting treatment, providing new look and design possibilities. In addition, visual effects can be created by mounting or casting bricks.

GRC panel is free to design with any size, shape, design or color. That means its applications also become endless. Here are a few other uses of GRC:

- Wall facade.

- Head poles, balustrades, balustrades, statues…

- Playground.

- Accessories for landscape decoration, garden decoration.

- Pool.

- Surround fireplace, hearth and fireplace face.

- Countertops.

- Bathtub.

- Floor tiles.

Basically, GRC materials have a variety of creative and design styles to meet most of the designs or designs that people can imagine. It is an effective solution for everything from new construction projects to historic restoration.

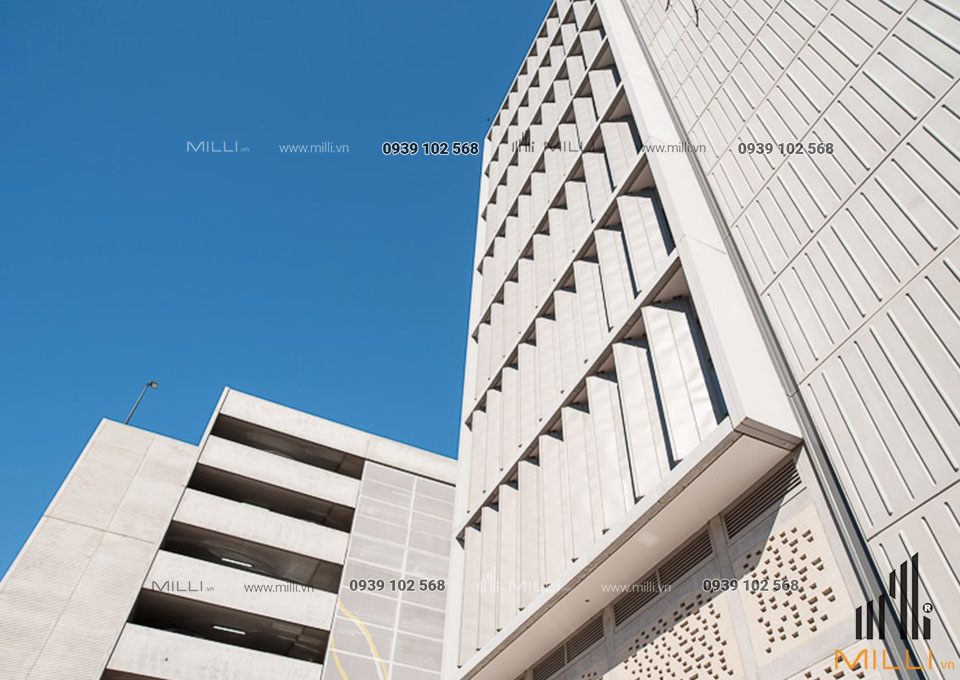

Application of GRC panel in design and construction

Commercially, GRC panels are used as large, lightweight panels for facades. These panels are non-structural, which can be designed to support their own loads, in addition to earthquake and wind loads, or used in the manufacture of glazed windows. The light weight of the cladding is due to the thinness of the material, not because GRC concrete has a lower density than conventional concrete. In terms of average weight, the two types of concrete are similar. Facade panels are often linked to a structural steel frame to support the panel as well as being hung up through joints.

GRC panel can be used to decorate mezzanine walls, column tops, undersides of arches, moldings, cantilever beams, cornerstones, balustrades, pillars, spines, domes… Besides, GRC is also an object. Ideal material for landscape designs such as potted plants, anchor posts, vases, tables, fountains, marine structures, pools, and rock formations. Product is used for restoration of historic buildings, replacing decorative elements from terracotta, carved stone and wood.

GRC panels come in a variety of colors, textures and shapes, and are 80% lighter than precast concrete panels. GRC is installed directly on the existing facade on the building without having to impose too much load on the building.

In addition, GRC panel brings freedom, creativity and natural harmony to architecture. The variability of this material creates the space for the individual and unique realization of each project without any boundaries and limitations.

The GRC panels facade can be in the shape of a flat plate or shaped element – lining, window shutters, articles, corners, shutters, etc. Glass fiber reinforced concrete elements are produced as one piece according to the client’s size requirements.

Benefits of GRC panel for restoration projects

There are numerous advantages for using GRC on your next restoration project:

You do not have to remove some of the old architectural features or building facades to use it. Instead, you can simply add the GRC material directly over the old features, such as wall cladding, columns, and some other architectural details.

The glass fibers in the material add unmatched impact, flexural, and tensile strength that increases durability and sustainability of the building and its features.

The material has high plasticity that allows it to be molded and sculpted into just about any shape. And can be used to create very complex ornamental designs and details. Molds are created often from pictures or drawings when the designs may be too worn so that the exact design can be matched and aligned with aspects of the building that are still intact.

Product is also thin and lightweight, which reduces building load and expands the applications it can be used for while also allowing for easy and quick installation to keep restoration projects on schedule and budget.

GRC panel can replicate any type of natural stone as well as metal and wood while also providing for the application of any texture or color.

Method of output GFRC panel

Hand spray cast GRC

All GRC panel elements are manufactured by hand spraying the GRC into a mould. This is the traditional method and requires experienced workers and extensive equipment.

For this spaying technique, we use a concentric chopper spray gun. Which is fed by a spool of glass fiber threads and the chopped strands are blended at the nozzle.

This method allows for a low water/cement-ratio and the GRC mix has a higher fiber content than can be achieved with premix. It also makes it possible for us to manufacture larger and more complex GRC elements. Compared to the Premix method, which has pre-chopped glass fibre strands blended into the mix. The spray-up technique produces thinner elements.

Vibration Casting

The defining factor of vibration casting is the use of premix concrete. The premix concrete mixture is poured into a mold. Then the mold is vibrated so that the concrete achieves consolidation.

This method is simpler and cheaper than sprayed GRC. However, the molds in this method should be water tight. Vibration casting should not be used with rock molds.

Hybrid Casting

Hybrid casting is the combination of spray-up and the use of a premix. A specialized spray head using a peristaltic pump is used to spray the concrete.

Hybrid casting introduces the benefits of spray-up GRC and vibration casting. While sprayed GRC requires highly skilled labor, hybrid casting is possible with moderate skill.

Due to using a spray instead of vibrations for the premix, the strength of the resultant concrete panel is higher than the vibration casting methods.

Does glass fiber reinforced concrete have any disadvantages?

The mechanical properties of GRC panel make it ideal for various requirements. However, one potential disadvantage for some users is the cost of GRC panel.

It can be expensive to use when compared to ordinary concrete. Of course, the added cost comes with additional strength and several other benefits, already mentioned in previous sections.

MILLI TILES – JOIN UP TO BUILD YOUR DREAM

After learning the introductory information about GRC panel and the outstanding advantages of this material. We find that this is a material that is well applied to the construction industry today. So how is GRC material applied in the construction industry in the world and in Vietnam?

Internationally, GRC has been commonly used because the product has many outstanding advantages compared to traditional building design materials. Many international famous construction sites apply GRC . materials

In our country at that time, GRC panel was being known by many people. Especially in the construction industry, because of its advanced technology protection product, designed quickly, conveniently, bringing art. And high aesthetics and durability for each project area.

MILLI TILES is a unit specializing in consulting and constructing GRC panels for projects. Contact us today to have a team of dedicated consultants advise you on this material sample.

MILLI CONSTRUCTION MATERIAL COMPANY LIMITED

📱 Hotline: 0939 102 568 📞

We will quote a specific % discount for you depending on the quantity or total value of the order

Contact us to order today, to get the best price support.

Instructions for construction of wind cement bricks, you can read and download below:

FILE INSTRUCTIONS FOR Brick Construction, DOWNLOAD HERE

Contact: Zalo: 0939 102 568

Fanpage: https://www.facebook.com/gachbonggio.hcm/

Youtube: https://www.youtube.com/channel/UC-ePtN2lIBwSp13ADgW7LSA