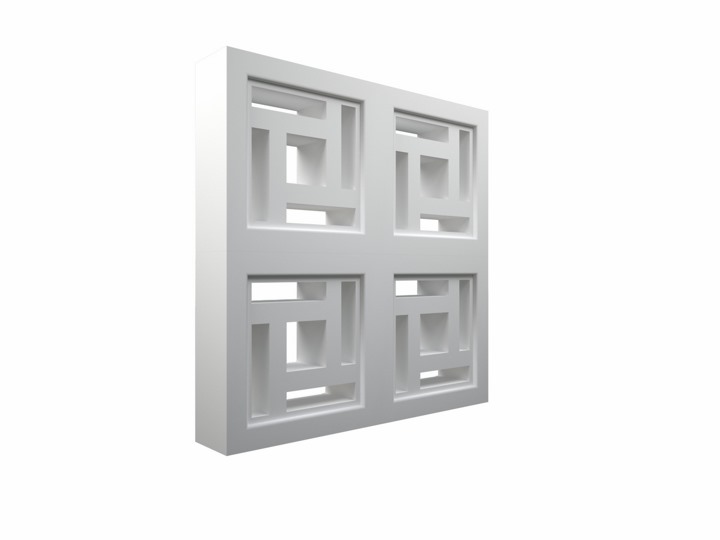

Cement breeze block are known for their distinctive pattern of hollow rectangular or square openings, which not only add visual interest but also provide ventilation and natural light. They come in a variety of sizes and shapes, including standard blocks, corner blocks, and half blocks.

Products can also be uses for decorative purposes, such as creating privacy screens or artistic installations. They can be painted or coated with different finishes to achieve a desired look.

Overall, cement breeze block are a versatile and practical building material that can be use in a range of construction projects, providing durability, strength, and design flexibility. The following article of MILLI TILES will provide full information about this tile. Stay tuned for more product features!

Whats is Cement breeze block?

Breeze cement block, also known as concrete blocks or ventilation blocks, are blocks made from a mixture of cement, sand, and water. They are used in a variety of construction and building applications, including foundations, walls, and retaining walls. Breeze cement blocks are often used to create openings in walls or ceilings to allow air to circulate and ventilate a space.

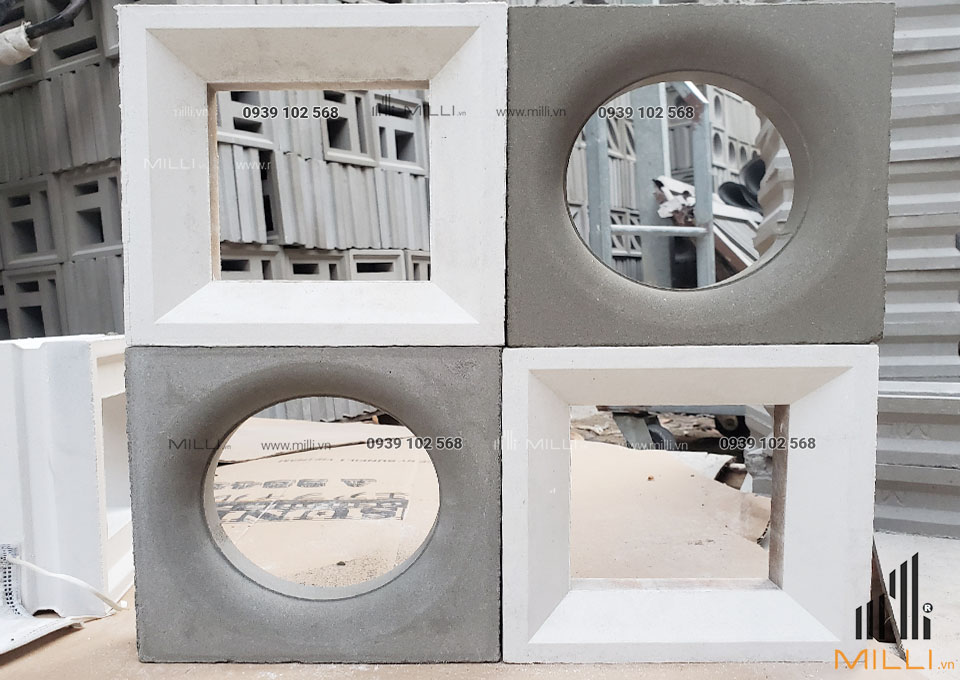

They are available in a variety of sizes and shapes, including square, rectangular, and circular, and can be used to create vents, louvers, or other openings. Ventilation cement blocks are often used in buildings to ensure proper ventilation and airflow, which can help to regulate temperature and humidity and improve indoor air quality.

They can also be used to create natural light and views in a building by incorporating windows or other openings. Addition, breeze blocks are a versatile building material that can be used to create openings in walls and ceilings to allow air to circulate and ventilate a space.

Breeze block dimensions

Cement breeze block, also known as concrete breeze blocks, come in a variety of sizes and dimensions. Some of the common sizes are:

- Standard block: 8 inches (20 cm) high, 8 inches (20 cm) wide, and 16 inches (40 cm) long

- Half block: 8 inches (20 cm) high, 8 inches (20 cm) wide, and 8 inches (20 cm) long

- Corner block: 8 inches (20 cm) high, 8 inches (20 cm) wide, and 16 inches (40 cm) long, with a diagonal cut to form a 90-degree angle

There are also other sizes available depending on the manufacturer and the intended use of the breeze blocks. It’s important to note that the actual dimensions may vary slightly due to manufacturing processes and other factors. It’s recommended to consult with the manufacturer or supplier to determine the specific dimensions of the breeze blocks needed for a particular project.

Advantages and disadvantages of products

Advantages of Cement breeze block

There are several advantages of using cement breeze blocks over other building materials:

Durability: Cement breeze block are known for their strength and durability, making them resistant to fire, moisture, and insect damage.

Affordability: Cement breeze block are relatively inexpensive compared to other building materials, making them a popular choice for construction projects.

Thermal insulation: The hollow cavities in breeze blocks provide good thermal insulation, helping to maintain a comfortable temperature inside the building.

Soundproofing: The solid mass of breeze blocks provides good sound insulation, reducing noise transmission from outside.

Design flexibility: Cement breeze block can be used for decorative purposes, with a wide range of sizes, shapes, and patterns available.

Speed of construction: Breeze blocks can be laid quickly and easily, reducing construction time and labor costs.

Sustainability: Cement breeze blocks are made from natural materials and can be recycled at the end of their life cycle, making them an environmentally friendly building material.

In addition, there are some models of cement ventilation bricks that have the ability to effectively block rain such as ventilation bricks for cakes, MILLI exclusive rain-blocking ventilation bricks.

Disadvantages

Heavy: Cement breeze block can be heavy and difficult to move, requiring special equipment or labor to handle them.

Limited insulation: While breeze blocks provide some thermal insulation, they are not as effective as other insulation materials.

Moisture retention: Breeze blocks can absorb and retain moisture, which can lead to mold and mildew growth if not properly sealed or ventilated.

Brittle: Cement breeze block can be brittle and prone to cracking under stress or impact.

Environmental impact: The production of cement, which is a key component of breeze blocks, is known to have a significant carbon footprint, contributing to greenhouse gas emissions.

Moreover Cement breeze block are a versatile and practical building material that can provide durability, strength, and design flexibility. However, their limitations should also be considered, such as their weight, limited insulation, moisture retention, and environmental impact.

Cement breeze block production process

The production process of cement breeze block involves several steps:

Mixing the raw materials

The raw materials for cement breeze blocks include cement, sand, water, and other aggregates such as crushed stone or gravel. These materials are mixed together in the right proportions to form a homogenous mixture.

Molding the blocks

The mixture is poured into molds that are designed to create the desired shape and size of the breeze blocks. The molds are vibrated to remove air pockets and ensure an even distribution of the mixture.

Curing the blocks

The blocks are then left to cure and harden for a period of time, usually in a temperature-controlled environment. The curing time can vary depending on the type of cement and the size of the blocks.

Stripping the molds

Once the blocks have cured, the molds are remove, and the blocks are ready for finishing.

Finishing the blocks

The blocks can be finished in a variety of ways, such as sand blasting, painting, or applying a textured surface. This step is optional, but it can improve the appearance and durability of the blocks.

Packaging and shipping

The finished blocks are inspected, packaged, and shipped to construction sites or suppliers for distribution.

Consequently, the production process of cement breeze blocks is a relatively simple and efficient process that requires careful attention to the mixing, molding, and curing stages to ensure the quality and strength of the blocks.

Application of Cement breeze block

Cement breeze blocks are a versatile building material that can be use in a variety of applications. Some of the common applications of cement breeze blocks are:

Exterior walls: Cement breeze blocks are often use for constructing exterior walls because of their strength, durability, and resistance to fire and moisture.

Interior walls: Breeze blocks can be use for interior walls to provide a decorative element and natural light.

Retaining walls: Breeze blocks can be use to create retaining walls that provide support for soil and prevent erosion.

Fences: Breeze blocks can be use to create fences for privacy or decorative purposes.

Garden walls: Breeze blocks can be use to create garden walls that provide a decorative element and support for plants.

Partitions: Breeze blocks can be use to create partitions inside a building to divide space.

Decorative features: Breeze blocks can be use to create decorative features such as privacy screens, planters, or artistic installations.

Sound barriers: Breeze blocks can be use as sound barriers to reduce noise from roads or other sources.

Consequently cement breeze blocks are a versatile building material that can be use in a range of applications, providing strength, durability, and design flexibility.

Is the price of Cement breeze block expensive?

The price of cement breeze block can vary depending on several factors such as the size. Shape, quality, and location of the supplier. In general, cement breeze blocks are relatively affordable compared to other building materials such as bricks or stones.

The price of a standard cement breeze block can range from $1 to $3 depending on the location and quantity purchased. The cost of other types of breeze blocks such as decorative or textured blocks can be higher.

It is important to note that the price of cement breeze blocks may also be affect by market fluctuations in the cost of raw materials such as cement and sand. In addition, transportation costs and taxes may also affect the final price of the blocks.

Therefore the price of cement breeze block is generally consider to be affordable and competitive compared to other building materials. It is suggest to compare prices from different suppliers and choose a reputable supplier that offers a good balance of price and quality.

What are the factors that affect the quality of cement breeze blocks?

Severalfactors can affect the quality of cement breeze blocks, including:

- Raw materials: The quality of the raw materials used to make the breeze blocks, such as the cement, sand, and aggregates, can affect the quality of the final product.

- Mixing ratios: The proportions of the raw materials used in the mix can affect the strength, consistency, and durability of the breeze blocks.

- Curing conditions: The temperature, humidity, and duration of the curing process can affect the strength and durability of the blocks.

- Manufacturing process: The manufacturing process, including the method of molding, vibration, and finishing, can affect the uniformity and consistency of the blocks.

- Storage and transportation: The way the blocks are storage and transportation can affect their quality, as exposure to moisture, sunlight, and other elements can cause damage or deterioration.

- Quality control: The level of quality control during the manufacturing process, including testing, inspection, and standards compliance, can affect the overall quality of the blocks.

Consequently ensuring high-quality cement breeze blocks requires careful attention to the selection of raw materials. The manufacturing process, and the quality control procedures. It is important to choose a reputable supplier that follows strict quality control standards and offers a warranty or guarantee on their products.

In summary, cement breeze block are a practical and cost-effective building material that offers several advantages over other building materials. They are versatile, durable, and easy to use, making them suitable for a wide range of construction projects. With proper attention to the selection of raw materials, manufacturing process, and quality control procedures. Therefore, Cement breeze blocks can provide a reliable and long-lasting solution for construction needs.

Milli Tiles – Manufacturer and supplier of high quality Cement breeze block

If you are looking for a manufacturer and supplier of high-quality cement breeze blocks. It is important to consider several factors to ensure that you choose a reputable and reliable supplier. MILLI TILES is commit to providing high quality products and best service to meet the needs of customers. We not only manufacture high-quality materials. But also offer optimal design solutions to help customers save costs and improve production efficiency.

MILLI CONSTRUCTION MATERIAL COMPANY LIMITED

📱 Hotline: 0939 102 568 📞

We will quote a specific % discount for you depending on the quantity or total value of the order

Contact us to order today, to get the best price support.

Instructions for construction of wind cement bricks, you can read and download below:

FILE INSTRUCTIONS FOR Brick Construction, DOWNLOAD HERE

Contact: Zalo: 0939 102 568

Fanpage: https://www.facebook.com/gachbonggio.hcm/

Youtube: https://www.youtube.com/channel/UC-ePtN2lIBwSp13ADgW7LSA