Milli Brand-GFRC & GRC panel-New materials bring modern design trends

GRC fiberglass concrete is currently being widely applied in the field of construction.

Fiberglass concrete brings a tremendous improvement to buildings. In addition, this material also blows a new breath into the field of interior and exterior design and decoration.

What is the GFRC?

GFRC (Glass Fiber Reinforced Concrete)

A unique type of concrete known as GFRC is a cementitious composite material reinforced with alkali-resistant fiberglass.

In addition to providing flexural, tensile, and impact strength, the fibers perform the same function as the reinforcement in reinforced concrete.

As a result, GFRC Concrete can be utilized to create strong, lightweight architectural concrete products, including slabs for building. Concrete ornamental objects can also be made using it.

COMPOSITION OF GFRC

GFRC concrete is a type of concrete that is reinforced with alkali-resistant fiberglass.

The fibers perform the same function as reinforcement in reinforced concrete while also adding flexural, tensile, and impact strength.

As a result, GFRC Concrete can be utilized to create lightweight, high-strength architectural concrete products such as construction slabs.

It is created by blending fine sand, cement, polymers (typically acrylic polymers), water, additional additives, and alkali resistant (AR) fiberglass.

In the field of interior and exterior décor, fiberglass concrete is still a highly sought-after material.

Excellent advantages of fiberglass reinforced concrete

- Can withstand high impact force

Fiberglass concrete is made out of alkali-resistant glass fiber as well as additional additives. As a result, it possesses extraordinarily high flexural strength and longevity.

Withstands great impact, so it can be bent or twisted very easily.

- Thinner and lighter than traditional concrete

An outstanding advantage of grc concrete is the thinness of the products made from them compared to traditional concrete.

Fiberglass components have contributed to a long-lasting surface that does not crack when subjected to environmental or external pressures.

As a result, grc fiberglass concrete is commonly used for details in facades and decorative structures such as moldings and balustrades.

Because of its lightweight nature, grc helps to minimize the burden for buildings that require huge facades or domes.

- Environmental friendliness

The basic components used to make fiberglass concrete are all environmentally safe.

As a result, this material satisfies the requirements for a green building.

Furthermore, as compared to typical concrete, fiberglass concrete utilizes less cement and is created from asbestos fibers that are non-toxic to the environment.

- GRC has a very high aesthetic value.

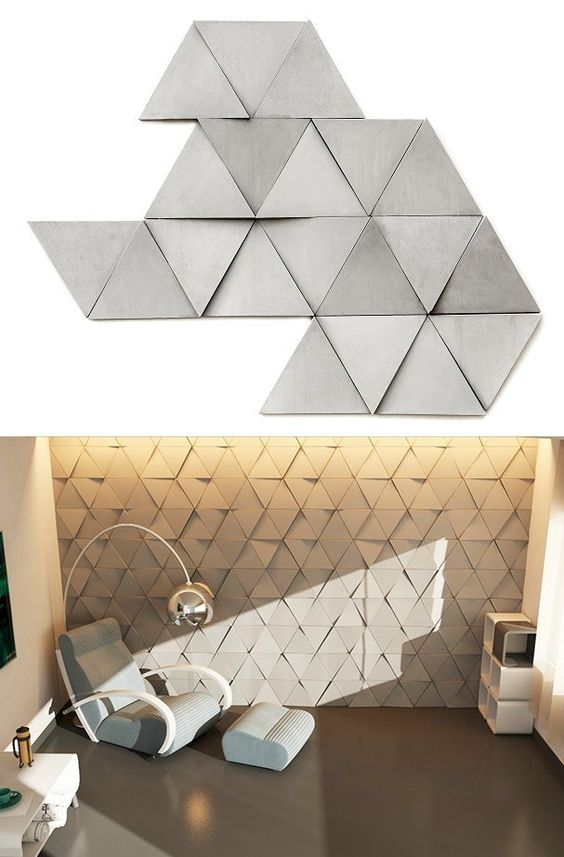

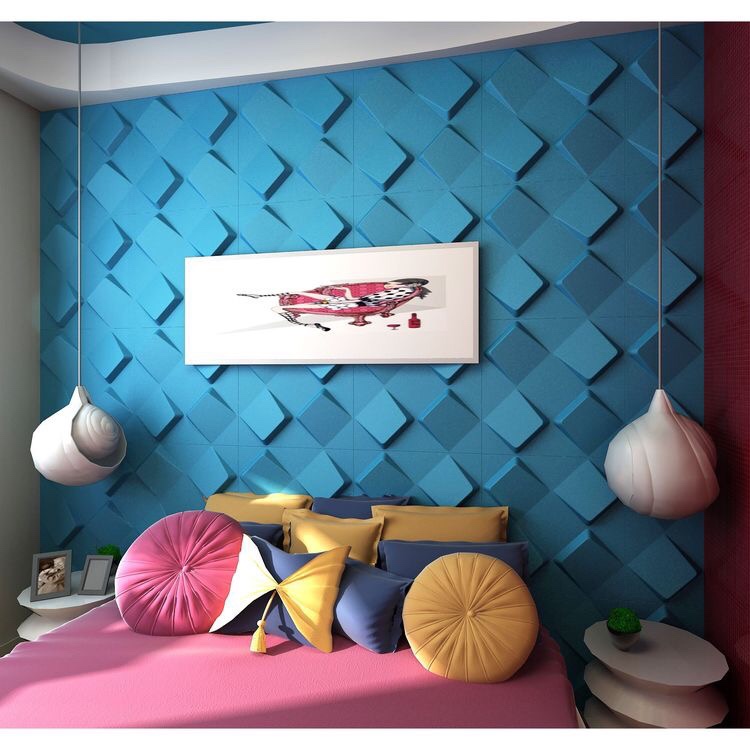

Glass fiber concrete material grc has been increasingly well-known and popular in the fields of building and interior and exterior design in recent years.

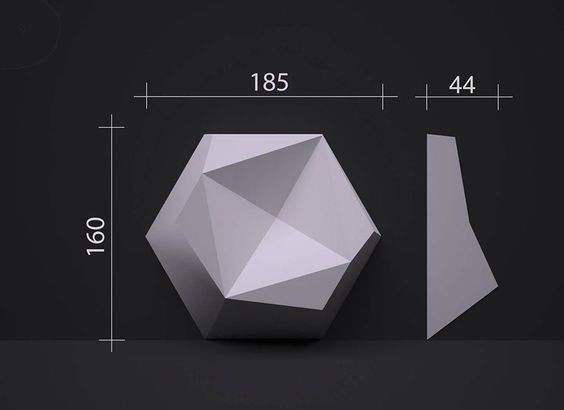

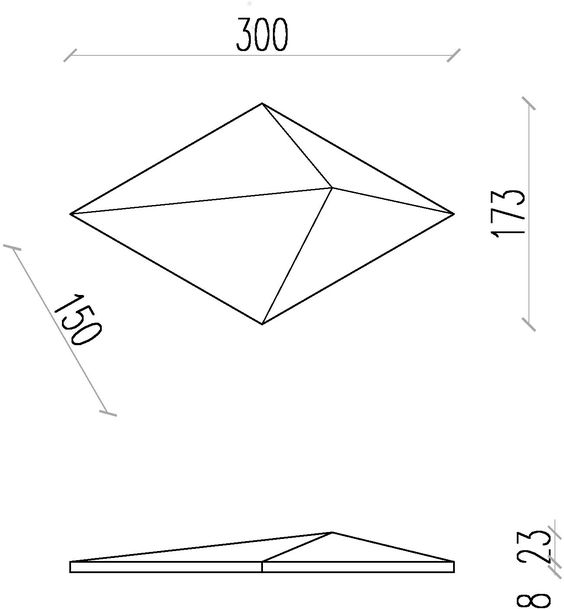

Produced using molding and injection processes, allowing for shape flexibility.

As a result, the designs and shapes created using fiberglass concrete are frequently highly diversified and attain a very high aesthetic.

The scale details of patterns, textures, and each line will be consistent without relying on the craftsman’s talent.

Because of its great aesthetics, it is now used in practically all major and small projects, from national projects to civil works or simply residential interiors. Fiberglass reinforced concrete products have an extraordinarily innovative and refined elegance.

- High durability for long-term use

The durability of the gfrc fiberglass concrete material is quite excellent.

Many amazing features, such as superb waterproofing. As a result, mold and rust are avoided when exposed to extreme weather conditions.

As a result, it is gradually being used to replace other traditional materials in the majority of projects.

Construction using fiberglass reinforced concrete

Currently, fiberglass concrete is still a very sought-after material in the field of interior and exterior decoration.

used in exterior

Currently, gfrc is a relatively new material in the world of architecture, but it is very popular and is gradually replacing traditional concrete. It is trusted by architects in modern constructions.

GRC is now used on the majority of large and well-known projects in various nations.

This form of concrete is increasingly being employed in civil works such as houses, bridges, and highways.

With the lightweight nature of grc, it helps to reduce the load for buildings that need large facades or domes.

3D Cement Brick – MILLI CONSTRUCTION MATERIALS CO., LTD

📱 Hotline: 0939 102 568

We will quote possible % discount to customers according to quantity or total value

Please link to order today, to be used at the best price.

Exam preparation materials, you can download below:

FIND OUT Brick BUILDING INSTRUCTIONS, DOWNLOAD HERE

Contact: Zalo: 0939 102 568

Fanpage: https://www.facebook.com/gachbonggio.hcm/

Gmail: vlxdmilli@gmail.com

Youtube: https://www.youtube.com/channel/UC-ePtN2lIBwSp13ADgW7LSA

.