Glass Fibre Reinforced Concrete – Durable Material For Construction

Glass Fibre Reinforced Concrete is a new construction material. Trusted by Architects and Investors in large design projects.

As society becomes more and more modern, the living space of each person is more and more important. Many home owners want to turn their living space into a work of art with many different decorative images. And the GFRC material sample is the perfect choice for you. It is environmentally friendly, excellent for reproduction and renovation.

What is Glass Fibre Reinforced Concrete?

Glass fibre reinforced concrete (GFRC) is a type of fibre-reinforced concrete. The product is also known as glass fibre reinforced concrete or GRC in British English. Glass fibre concretes are mainly used in exterior building facade panels and as architectural precast concrete. Somewhat similar materials are fibre cement siding and cement boards.

The popularity of glass-fibre reinforced concrete (GFRC) has grown in the past few years as more and more people discover its versatility. Strength and relative ease of manufacture. GFRC makes it possible to create stronger and lighter elements and complex 3D pieces easily.

Advantages and Disadvantages of this material

Advantages

There are lots of good reasons to use GFRC for thin sections of concrete:

Lighter weight: Glass fibre reinforced concrete (GFRC) can be cast in thinner sections and is therefore as much as 75% lighter than similar pieces cast with traditional concrete. An artificial rock made with GFRC will weigh a small fraction of what a real rock of similar proportions would weigh, allowing for lighter foundations and reduced shipping cost.

High strength: GFRC can have flexural strength as high as 4000 psi. And it has a very high strength-to-weight ratio.

Reinforcement: Since GFRC is reinforce internally, there is no need for other kinds of reinforcement. Which can be difficult to place into complex shapes.

Consolidation: For sprayed GFRC, no vibration is need. For poured, GFRC, vibration or rollers are easy to use to achieve consolidation.

Equipment: Expensive equipment is not need for poured or vibrated GFRC with a face coat.

Durability: There’s never a durability issue. Water can’t get in-there are no cracks-and that’s a durable material. GFRC will outlast precast concrete, cast stone, even some natural stone. Durability has been increas through the use of low alkaline cements and pozzolans.

Sustainable: Because it uses less cement than equivalent concrete. And also often uses significant quantities of recycled materials (as a pozzolan), GFRC qualifies as sustainable.

Disadvantages of Glass fibre reinforced concrete (GFRC)

Besides the outstanding advantages, they also have some disadvantages such as:

Cost: GFRC as a material, however, is much more expensive than conventional concrete on a pound-for-pound basis. But since the cross sections can be so much thinner, that cost is overcome in most decorative elements.

Production methods of Glass fibre reinforced concrete (GFRC)

There are three methods to produce Glass Fibre Reinforced Concrete: Spray-up, Vibration casting and Pre-mixing.

Spray-up

The traditional way, and probably still the best way. To produce prefabricated GFRC panels is to manually inject GFRC into the mold. This is how most prefabrication GFRC architectural cladding is made and also most decorative prefabricated GFRC. With the direct injection method. You need a concentric pump gun. Powered by a GFRC roving that is drawn into the pump gun and mixed at the nozzle. This blend has a higher fibre content (4 to 6%) than the pre-mix. And is the recommended method for larger plates. However, it requires experienced workers. Expensive equipment and strict quality control.

Vibration casting

Vibration casting uses pre-mixing GFRC which is poured into the mold and fired to achieved fusion. This is a much simpler method. But requires water tight mold and does not work well with stone molds.

Pre-mixing

GFRC is spray pre-mixing, with fibres chopped into the mix. A peristaltic pump and a special nozzle are require. This method requires less expertise than the hand spray method. Besides, it also offers higher durability than the vibration casting method.

Application for Glass Fibre Reinforced Concrete (GFRC)

After learning the introductory information about Glass Fibre Reinforced Concrete. And the outstanding advantages of this material. We see that this is a material that is well use in the construction industry today. So how is Glass Fibre Reinforced Concrete (GFRC) application in the construction industry in the world and in Vietnam?

In today’s countries, this material plays an important role in decoration and interior materials. Especially in regions with harsh climates. The weather often changes. GFRC decorative panels can survive and avoid any impact from the outside. Materials always retain aesthetics and sustainable features. Below are design ideas conceive by construction units and architects from GFRC.

Because, GFRC offers the same decorative versatility as conventional concrete. It can be former into nearly any shape and stained or integrally colored. Various tints of gray, white, and buff can be achieve by using color cements or pigments. The surface finish can be lightly textur or polished smooth to expose the aggregate. And GFRC can be seeded with color decorative glass or stone to create granite-like effects.

Kitchen Exhibits Beauty of Gray Concrete

This stunning kitchen features GFRC countertops that were simply seale to enhance the natural gray color. Use Glass Fibre Reinforced Concrete for most of countertop. GFRC mix, which incorporates polymer. Sand cement, fibres, and a plasticizer. With different techniques, we can get GFRC to pretty much look like any kind of concrete you would want.

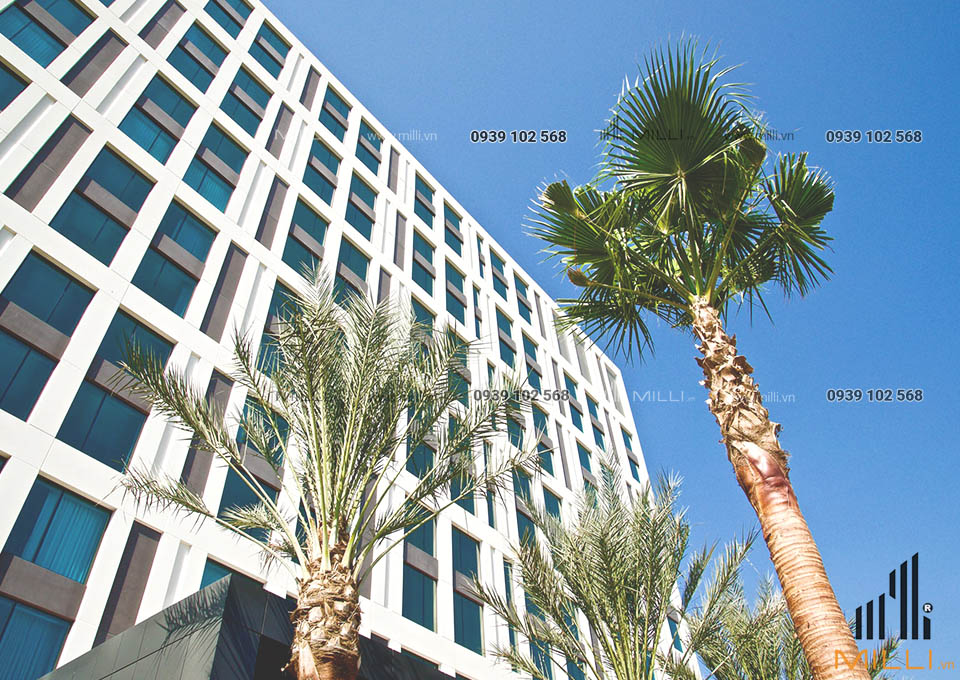

Facade using Panel GFRC

GFRC Panel is a high-grade building material for architectural facade applications. Bringing a modern and luxurious beauty to the project.

Sigh only

Architectural details: moldings, column tops made of GFRC materials are beautiful decorative details, meeting all architectural styles.

Bedroom wall decoration of Glass Fibre Reinforced Concrete

The bedroom is a place to rest after a tiring day at work. By using GFRC with built-in color. Create a feeling of cool space, comfortable, full of relaxation. A proprietary decorative fibre reinforced concrete mix was used without mixing.

Structure

Glass Fibre Reinforced Concrete is the choice for building a solid structure with high durability. Be affect by the environment and ensure the construction progress. GFRC is extremely versatile and has many use cases due to its durability, weight and design.

An expert in the field of materials technology. Milli Tiles products are of high quality. We have the ability to customize materials to meet customer needs very quickly. An experienced design team is ready to adapt your ideas and accompany your projects. Please contact us to answer any questions about Glass Fibre Reinforced Concrete (GFRC).

Milli Tiles – The unit that supplies and constructs Glass Fibre Reinforced Concrete GFRC materials for projects

MILLI CONSTRUCTION MATERIAL COMPANY LIMITED

📱 Hotline: 0939 102 568 📞

We will quote a specific % discount for you depending on the quantity or total value of the order

Contact us to order today, to get the best price support.

Instructions for construction of wind cement bricks, you can read and download below:

FILE INSTRUCTIONS FOR Brick Construction, DOWNLOAD HERE

Contact: Zalo: 0939 102 568

Fanpage: https://www.facebook.com/gachbonggio.hcm/

Youtube: https://www.youtube.com/channel/UC-ePtN2lIBwSp13ADgW7LSA