GFRC panels manufacture is a step forward for today’s new building materials manufacturing industry. As we all know, GFRC panels are durable, environmentally friendly products. It is a typical and impressive facade architectural design solution in recent years. So for more information about the pros and cons of this material, how? How is the production process? Cost and applications? Let’s refer to the entire article below with MILLI TILES!

What is GFRC?

GFRC stands for Glass Fiber Reinforced Concrete. It is a type of concrete that is reinforced with glass fibers rather than steel. GFRC was first developed in the 1940s but gained popularity in the 1970s as a building material due to its strength, durability, and versatility.

The composition of GFRC typically includes a mixture of cement, sand, water, and glass fibers. The glass fibers are added to the mix to improve the strength and durability of the concrete. Other additives such as plasticizers or pigments may also be added to the mix to improve its properties.

GFRC is known for its lightweight nature, making it easier to handle and install compared to traditional concrete. It also has excellent insulation properties, which can help reduce energy consumption in buildings. GFRC is highly resistant to damage from weather, fire, and other environmental factors, making it a popular choice for exterior cladding and architectural features.

Overall, GFRC is a popular building material due to its strength, durability, versatility, and lightweight nature. It is a sustainable and environmentally-friendly choice that offers several benefits over traditional concrete.

What are the advantages of using GFRC panels over other materials?

GFRC (Glass Fiber Reinforced Concrete) panels offer several advantages over other materials, including:

Strength: GFRC panels are stronger than traditional concrete panels due to the addition of glass fibers. This makes them less prone to cracking and more resistant to impact and other types of damage.

Durability: GFRC panels are highly durable and can with stand exposure to harsh weather conditions, UV radiation, and other environmental factors. They are also resistant to corrosion and have a long service life.

Lightweight: GFRC panels are lightweight compared to other cladding materials such as stone or brick. This makes them easier to handle and install, and can also reduce the load on the building structure.

Versatility: GFRC panels can be molded into a variety of shapes and sizes, making them highly versatile. They can also be finished to mimic other materials such as stone, wood, or metal.

Sustainability: GFRC panels are made from natural materials and are highly energy-efficient. They also have a low carbon footprint compared to other building materials.

Cost-effective: GFRC panels are often more cost-effective than other materials such as stone or metal. They have a lower installation cost, require less maintenance, and have a longer service life.

Overall, GFRC panels offer a range of advantages over other materials due to their strength, durability, versatility, and sustainability. They are a popular choice for architects and builders looking for a high-performance, cost-effective, and environmentally-friendly building material.

Methods of GFRC panels manufacture

There are several methods of GFRC (Glass Fiber Reinforced Concrete) panel manufacture, including:

GFRC panels manufacture by spray-up method

This is the most common method of GFRC panel manufacture. In this method, the GFRC mixture is sprayed onto a mold using a spray gun. The fibers are added to the spray gun and mixed with the GFRC mixture as it is sprayed onto the mold. This method is suitable for large-scale production and allows for the creation of complex shapes and designs.

Premix method

In this method, the fibers are first mixed with the dry ingredients, then water and other additives are added to create a slurry. The slurry is then poured into the mold and compacted using a vibrating table. This method is suitable for small-scale production and allows for precise control over the mix.

Hybrid method

This method combines the spray-up and premix methods. In this method, the fibers are first mixed with the dry ingredients, then the slurry is sprayed onto the mold using a spray gun. This method allows for the benefits of both the spray-up and premix methods and is suitable for medium-scale production.

Vacuum bagging method

In this method, the GFRC mixture is poured into a vacuum bag and sealed. The bag is then placed in a vacuum chamber, which removes the air from the bag and compacts the mixture. This method is suitable for producing thin, lightweight panels and is often used for architectural features.

Extrusion method

In this method, the GFRC mixture is extruded through a machine to create panels of a specific size and shape. This method is suitable for mass production and is often used for producing panels for commercial and industrial buildings.

The choice of method will depend on the specific requirements of the project, including the size, shape, and quantity of panels required. Each method has its advantages and disadvantages, and it is important to choose the most appropriate method for the specific application.

What is GFRC panels manufacture? Production process?

GFRC (Glass Fiber Reinforced Concrete) panels manufacture is the process of creating panels made of a mixture of cement, sand, water, and glass fibers. The mixture is sprayed onto a mold and allowed to cure, creating a strong, durable, and lightweight panel.

The manufacturing process typically involves the following steps:

Design: The first step in the GFRC panel manufacture process is to create a design for the panel. This can be done using computer-aided design (CAD) software or by hand.

Mold Making: Once the design is completed, a mold must be created. The mold is typically made from silicone, polyurethane, or fiberglass and is used to shape the GFRC mixture.

Mixing the GFRC: The GFRC mixture is made by mixing cement, sand, water, and glass fibers together. Other additives such as plasticizers or pigments may also be added to the mix.

Spraying the Mixture: The GFRC mixture is sprayed onto the mold using a spray gun or a specialized machine. The thickness of the panel is controlled by the number of layers applied.

Curing: After spraying, the GFRC panel is left to cure. This can take several days depending on the thickness of the panel and the weather conditions.

Demolding: Once the panel is fully cured, it can be removed from the mold. The mold can be reused to create more panels.

Finishing: The GFRC panel can be finished in a variety of ways such as sand blasting, acid etching, or polishing.

Quality Control: The GFRC panel is inspected for defects such as cracks or air pockets. Any defects are repaired before the panel is shipped to the customer.

GFRC panel manufacture requires specialized equipment and experienced personnel. It is important to follow all safety procedures when handling GFRC mixtures and to ensure that the panels are properly cured before they are used.

What are the environmental benefits of using GFRC panels?

GFRC (Glass Fiber Reinforced Concrete) panels offer several environmental benefits over other materials, including:

Reduced carbon footprint: GFRC panels have a lower carbon footprint compared to other building materials such as steel or aluminum. The production process for GFRC panels requires less energy and emits fewer greenhouse gases.

Sustainable materials: GFRC panels are made from natural materials such as cement, sand, and glass fibers. These materials are abundant and readily available, making GFRC panels a sustainable choice.

Energy efficiency: GFRC panels have excellent insulation properties, which can help reduce energy consumption in buildings. This can lead to lower heating and cooling costs and a reduced carbon footprint.

Durability: GFRC panels have a long service life and require minimal maintenance, reducing the need for replacements or repairs. This can help reduce waste and minimize the environmental impact of building materials.

Recyclable: At the end of their service life, GFRC panels can be recycled and used in the production of new materials. This can help reduce waste and conserve natural resources.

GFRC panels offer several environmental benefits over other building materials. They are a sustainable, energy-efficient, and durable choice that can help reduce the environmental impact of buildings and construction projects.

Application of the GFRC panels manufacture

The manufacture of GFRC panels offers very large applications. They are used in a variety of applications in the construction industry, including:

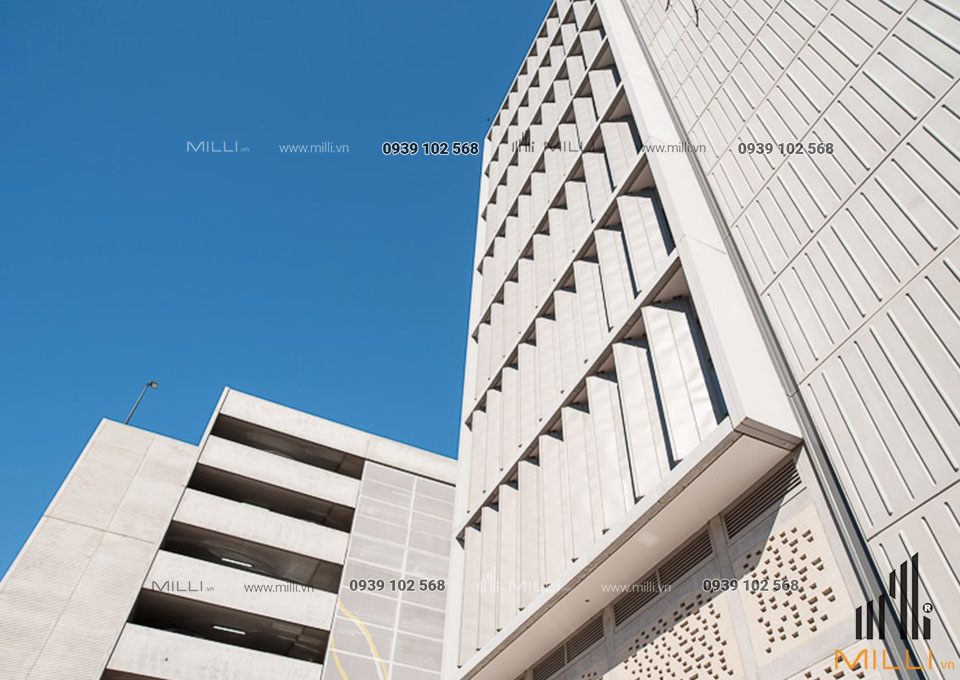

Exterior Cladding: GFRC panels are commonly used as an exterior cladding material for buildings. They can be molded into a variety of shapes and sizes and can be finished to mimic other materials such as stone, wood, or metal.

Architectural Features: GFRC panels can be used to create a variety of architectural features such as cornices, balustrades, and columns.

Signage: GFRC panels can be used to create large-scale signage for buildings or outdoor areas. They can be painted or finished with vinyl graphics to convey branding or messaging.

Furniture: GFRC panels can be used to create furniture such as benches, tables, and planters. They can be molded into a variety of shapes and sizes and finished to match the surrounding environment.

Art Installations: GFRC panels can be used to create large-scale art installations such as sculptures or murals. They can be painted or finished to create a variety of textures and colors.

Landscape Features: GFRC panels can be used to create landscape features such as retaining

Overall, GFRC panels offer a durable and versatile solution for a wide range of construction applications. They are lightweight, strong, and can be molded into a variety of shapes and sizes, making them a popular choice for architects and builders.

How does the cost of GFRC panels compare to other construction materials?

The GFRC panels are competitive with other construction materials in terms of cost.

Comparedprecast concrete, GFRC panels can be more cost-effective due to their lightweight nature, which reduces shipping and handling costs. Additionally, GFRC panels can be molded into a wide range of shapes and sizes, which can reduce the need for additional fabrication or customization.

In terms of installation costs, GFRC panels are often more affordable than heavier materials such as stone or brick, as they require less labor and equipment to install. GFRC panels can also be installed faster than traditional building materials, which can further reduce installation costs.

While the initial cost of GFRC panels may be slightly higher than some other materials such as vinyl or wood, the long-term benefits of GFRC, including its durability and low maintenance requirements, can make it a more cost-effective choice over the lifetime of the building.

MILLI TILES – PRESTIGE UNIT, SPECIALIZING IN CONSTRUCTION OF GFRC PANEL FOR PROJECTS

The birth of GFRC panels manufacture is extremely reasonable. There are now many builders and architects who are aware of the properties of GFRC and use this concrete mix in their structures. If you need strong and lightweight concrete, precast GFRC could be the ideal material for your project. You can contact MILLI TILES to learn about different GFRC products and at the same time we also accept GFRC construction for projects. Please contact us today for advice on GFRC products!

MILLI CONSTRUCTION MATERIAL COMPANY LIMITED

📱 Hotline: 0939 102 568 📞

We will quote a specific % discount for you depending on the quantity or total value of the order

Contact us to order today, to get the best price support.

Instructions for construction of wind cement bricks, you can read and download below:

FILE INSTRUCTIONS FOR Brick Construction, DOWNLOAD HERE

Contact: Zalo: 0939 102 568

Fanpage: https://www.facebook.com/gachbonggio.hcm/

Youtube: https://www.youtube.com/channel/UC-ePtN2lIBwSp13ADgW7LSA