Glass fibre concrete panels cladding is well known in the modern construction industry. This is a new building material, trusted by architects in recent design projects. Especially large projects with modern facades. As society develops, the living space of each person is more and more appreciated. Many home owners want to turn their living space into a work of art with many different decorative images. And the GFRC material sample is the perfect choice for your project.

High quality new interior and exterior decoration materials. Glass fibre concrete panels are artistic, durable and environmentally friendly. GFRC wall panels are fibre glass concrete (GFRC) handcraft by skillful hands of skilled craftsmen and architects. This product is capable of creating a gentle, simple and artistic 3D effect. Currently, in Vietnam, this material is still very new and not well known. Join Milli Tiles to learn more about the product below!

What is glass fibre concrete? The properties of glass fibre concrete panels?

Product overview

GFRC stands for Glass Fibre Reinforced Concrete. This type of concrete consists of short glass fibers instead of reinforcement. Is a new building material in Vietnam today. They are also known as glass fibre concrete. A coarse fiber reinforced concrete mixed in a mixture of fine aggregates: cement, clean water, clean sand, polymers, coloring agents and plasticizers. It is concrete that uses alkali resistant glass fibre as reinforcement instead of standard metal reinforcement.

Glass-fibre reinforced concrete is an innovative and lightweight concrete. With the opportunity to cast virtually unlimited shapes, profiles and textures – GFRC can bring your project to life without limitations. It uses alkali-resistant glass fibres as reinforcement instead of the steel used in conventional precast. Uniquely agile, versatile and sustainable, this Glass fibre concrete panels is quickly becoming a choice solution for architects, designers and builders globally.

Who invented GFRC?

Adding reinforcement to concrete to improve its mechanical properties is an old idea. Reinforced concrete was uses to make historical structures like the Colosseum and Pantheon – structures that still stand today. Initially, Type E and Type C glass were add to concrete to improve flexibility. But the experiment failed due to the resulting high alkalinity.

In the 1960s, Europe began experimenting with Zirconium-based glass that could handle an alkali attack. The experiments finally became successful in the 1970s, and it was discover that glass with 17% Zirconium was perfect for the purpose.

The properties of glass fibre concrete panels?

Glass fibre reinforced concrete panels is well known for its high compressive strength-to-weight ratio. This benefit results from the high cement mixture and low water content.

Other benefits are its high flexural strength (bending strength) and high tensile strength. GFRC also has appreciable load-bearing qualities. The direction resistance to load bearing is highly versatile, depending on the orientation of the glass fibres. Additionally, to bring out the high tensile strength of GFRC, it is vital to ensure that the fibers are stiff.

The primary purpose of the fibers is to provide tensile strength in lightweight panels. The addition of acrylic polymer enhances the flexural strength of the GFRC. Under certain conditions. It is more resistant to cracking than standard reinforced concrete.

What is the thickness of the glass fibre concrete panels?

The minimum thickness range of GFRC panels varies between 3/4″ to 1″. If the thickness goes below this limit, there is a chance that the concrete panel may break during transportation or handling.

The minimum thickness possible with GFRC is lower than conventional concrete (1.5″ to 3″). This is an excellent benefit since the thinner GFRC panels provide the same strength as traditional concrete panels.

Advantages and benefits of Glass fibre concrete panels

Glass-fibre reinforced concrete is a truly unique and versatile material that offers a number of benefits over its conventional counterparts. It is strong and lightweight, making it faster and more affordable to install while still offering durability and strength to the point of being almost indestructible.

Some of the key advantages include :

Strong

The unique chemical composition and high dose of glass fibres makes for a high impact material with an impressive strength-to-weight ratio. GFRC has a tensile strength that is three to four times greater than steel-reinforced concrete. GFRC has an undeniable strength and while its relative density is similar to concrete, GFRC panels can be made much thinner. Glass-reinforced concrete can be up to 80% lighter than traditional concrete, meaning greater ease in handling and installation. Not only is it a tough and easy to handle material, but it is more cost-effective thanks to its lighter weight.

Versatile

The combination of strength and flexibility provides virtually unlimited opportunity when creating a lighter, thinner and architecturally complex structure. Without the need of steel or other rigid components, GFRC offers creative possibilities for designs of any size, with intricate details, complexing shapes or smooth curves. There are also a range of finishes available, with a variety of textures, colours and surface details.

Sustainable and energy efficient

The production of glass-fibre reinforced concrete requires a lower consumption of energy and natural raw materials, it’s often produce using recyclable materials. The composite is based on natural earth oxides that are consider to be safe for the environment. It is a sustainable solution that also has a much lower environmental impact than traditional concrete precasts.

Durable and non-combustible

Unlike conventional concrete, GFRC is not at risk of corrosion and is specially formulates for greater protection and wear. The material requires minimal maintenance and can be formulates to offer additional resistance to weather, sound, fire, chemicals and impact.

How is glass fibre reinforced concrete panels manufactured?

GFRC panels comprises a concrete matrix combined with alkali-resistant glass fibres. This blend of glass fibres and concrete is what gives this unique compound its lead-bearing strength and flexibility. There are two methods for casting commercial GFRC: spray up and premix.

Spray up

Using a specialised spray gun, the fluid concrete mixture is sprayed into a mould. The spray gun has an integrated fibre chopper to continuously feed glass fibres into the concrete slurry. This method allows for a high fibre load to produce the strongest possible result and is typically used in large scale projects.

Premix

The chopped glass fibres are incorporated into a concrete slurry during the mixing and preparation process. This slurry is then poured into moulds or sprayed. This method results in slightly less strength due to the randomness of the fibres, however, it is more cost effective than the latter.

The finishes of GFRC are equally diverse as it can be stained, coloured, left natural or smoothed over for a flawless finish. Often glass-fibre reinforced concrete is used for architectural panels and cladding; cast in multiple, thin layers the surface finish can be sandblasted, acid etched or polished with various coloured cements and pigments available.

Uses and applications of Glass fibre reinforced concrete panels

Because of its strength and composition, glass fibre reinforced concrete panels presents designers and builders with a material with which to create the most ambitious designs. With the ability to be cast and finished in virtually unlimited styles and shapes, GFRC can be use to replicate traditional, historic features or modern, futuristic designs.

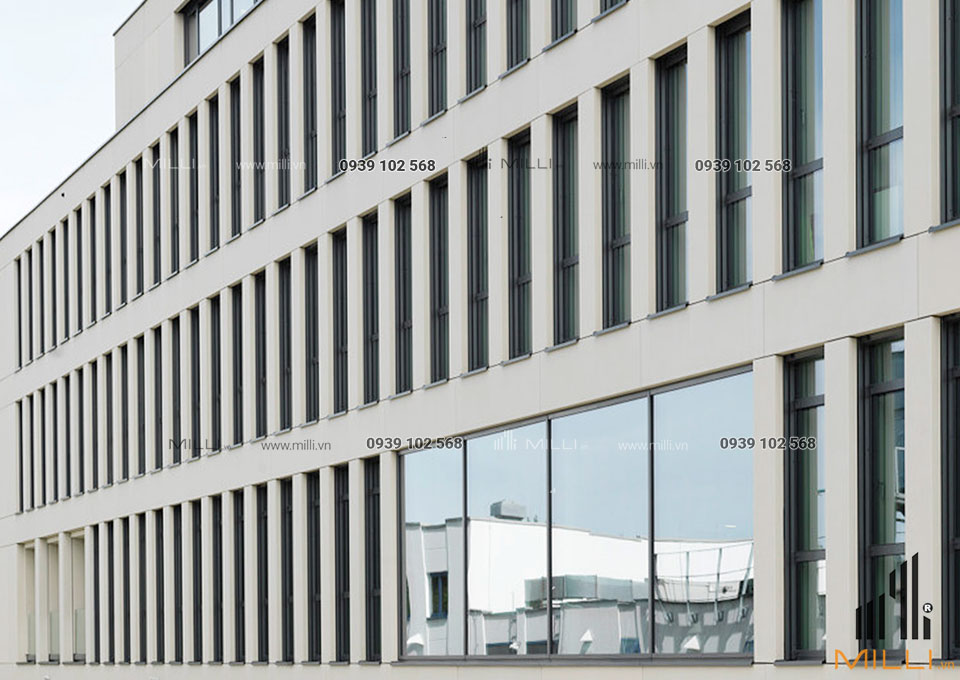

Adapted to suit any project, GFRC panels has a range of uses and applications. Commercially, it is often uses in exterior building facade panels as an architectural concrete. It is moulde into thin, lightweight panels with the opportunity for more creative freedom than conventional concrete.

Glass fibre reinforced concrete is incredibly versatile thanks to its strength, weight and design. It’s a cutting- edge building solution and has been uses for commercial offices, retail shopping centres, cultural buildings and churches, complex roofing and facade elements, noise walls, education facilities, government buildings and more.

GFRC has been use in Australia and countries around the world for 40 years for a wide range of applications including building facades, arches, tunnels, pits, monuments, sound barriers, planters and furniture. We have provided GFRC solutions for shopping centres, cultural buildings, education facilities, railway stations and government buildings.

Our GFRC capabilities include:

- Heritage restoration and reproduction works

- Unique architectural facades

- Complex roofing, cladding, ceiling and facade elements

GFRC material is a lightweight alternative to concrete that offers savings on structure design weight and can be use for three-dimensional and multi-coloured elements.

GFRC panels is incredibly versatile and has a large number of use cases due to its strength, weight, and design. The most commonplace you will see this material is in the construction industry. It’s use in very demanding cases such as architectural cladding that’s hanging several stories above sidewalks or even more for aesthetics such as interior furniture pieces like GFRC coffee tables.

Glass fibre concrete panels installation details

Glass fibre concrete panels has become more and more popular choice as an architectural finish material. People consider Glass fibre reinforced concrete cladding as a relatively new type of construction material. Although, the construction industry has been using it for over 50 years it’s only getting more attention in the 21st century. GFRC cladding is very versatile and that is why it’s gaining popularity among architects and specifiers. Due to its high elastic properties designers use GFRC cladding in solutions where resistance to live loads is necessary.

GFRC cladding systems require high quality standards in manufacture and meticulous record keeping. If you use glass fibre reinforced concrete cladding or panels in your projects it is important to employ subcontractor or installation crew with GFRC cladding experience.

How to install cladding glass fibre concrete panels?

It’s not easy to answer such question in a short way. Every project is different and every design is different as well. However, there are some common parts which you can apply to various GFRC cladding projects.

Before you start with any installation be sure that your design is verified against compliance with the project specification and architects requirements. It is not enough just to get design acceptance. You should also make sure that you can meet all the testing criteria. What is more, it is crucial to check how easy or how complicated it is to build GFRC cladding according to the design. For such an activity you can build a mock-up or a prototype.

MILLI TILES – Distributor and contractor of quality and reputable Glass fiber concrete panels for projects

An expert in the field of materials technology. We have the ability to customize materials to meet customer needs very quickly. An experienced design team is ready to adapt your ideas and accompany your projects.

Above are the shares of Milli Tiles on the topic of Glass fiber concrete panels that many people are interested in today. If you need advice on the Glass fiber concrete panels model suitable for your project, do not hesitate to contact us for support today or the information below.

MILLI CONSTRUCTION MATERIAL COMPANY LIMITED

📱 Hotline: 0939 102 568 📞

We will quote a specific % discount for you depending on the quantity or total value of the order

Contact us to order today, to get the best price support.

Instructions for construction of wind cement bricks, you can read and download below:

FILE INSTRUCTIONS FOR Brick Construction, DOWNLOAD HERE

Contact: Zalo: 0939 102 568

Fanpage: https://www.facebook.com/gachbonggio.hcm/

Youtube: https://www.youtube.com/channel/UC-ePtN2lIBwSp13ADgW7LSA